What is SOMMER all about?

In a sustainable future, there will continue to be industrial processes that release CO2, for example in cement production, whereas the chemical industry will continue to require carbon as a raw material – i.e. sustainably from CO2. The use of this unavoidable CO2 for the production of chemical raw materials enables a CO2 circular economy. CO2 is by nature an unreactive molecule. In order for it to react, it must be exposed to high temperatures. And to make this process sustainable, energy sources must be used that have no impact on greenhouse gas emissions.

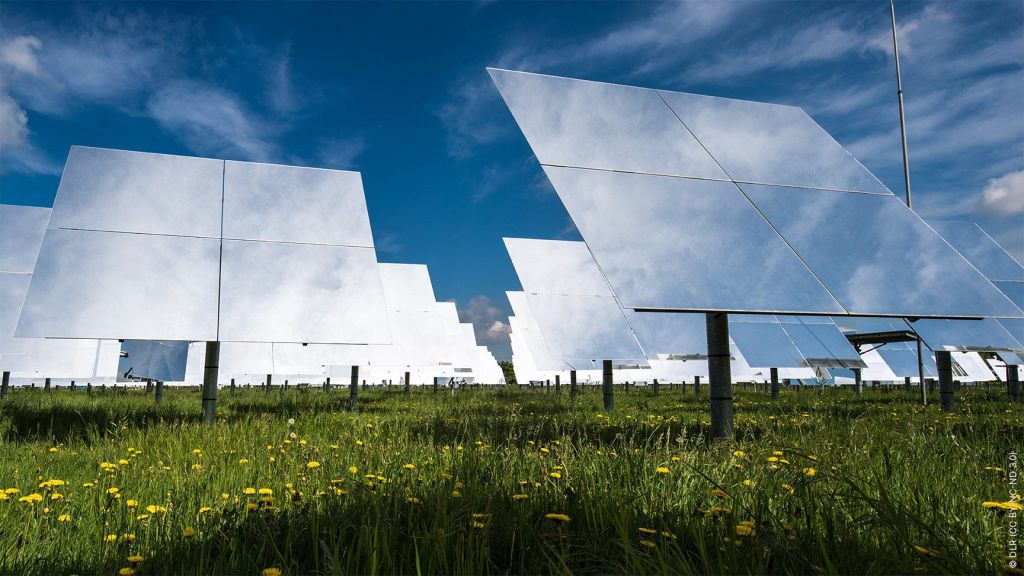

SOMMER’s innovation: heat from concentrated sunlight is used directly as an energy source. A special membrane makes it possible to reduce the required heat input from over 2,500°C to below 1,500°C. The advantage over electrolysis processes, which split CO2 and water using green electricity, is that no electricity is required for the process itself. This is an advantage as the heat from the concentrated sunlight can easily be stored for longer operating hours in thermal energy storages. In addition, the core components of this solar technology come from European companies, making it a robust technology. The companies involved in the project – hte, BASF, TITAN and Haldenwanger – are sharing their expertise to support the upscaling of the technology so that it can be transferred from research to industry as quickly as possible. The project’s research partners – DLR, FZJ, CSIC, IREC – and the industrial partners are set to take sustainable membrane-based syngas production to the next level.

Project Facts

Grant number: 101118293

Overall budget: 4.711.516,25 €

Duration: 48 months

Start date: 01.11.2023

End date: 31.10.2027

Call: HORIZON-CL5-2022-D3-02

Topic: Direct Renewable Energy Integration Into

Process Energy Demands Of The Chemical Industry